Infrared Thermography Scanning

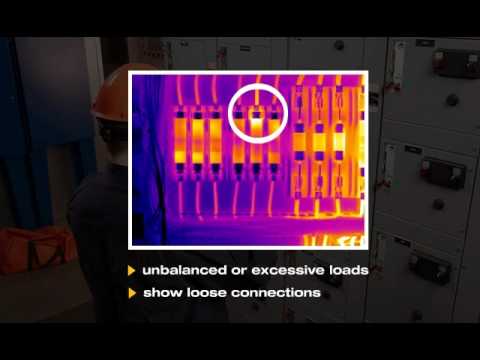

Infrared thermography is one of best diagnostic tools for predictive maintenance. With an infrared camera, we can check systems and devices to evaluate their current state using the thermal model. Infrared thermography provides a real-time evaluation of systems and devices. In electrical systems, IR thermography can detect problems such as overheated components, poor connections, overload, unbalanced loads, and overheat protection switches, which, if left unattended, can result in a total asset loss.

Advanced notification when developing problems allows you to make the necessary adjustments or repairs against costly, sometimes catastrophic failures.

Owing to the high costs associated with electrical and mechanical failures, Infrared Thermography can mean significant savings. And because thermographic scans are performed while your device is operating, there is no lost production or machine downtime.

Save Money

• Prevent Equipment Failures

• Save on Emergency Repairs

• Reduce down time

• Plan and schedule repairs

• Improve electrical and mechanical system efficiency

Save Time

• Identify and prioritize areas requiring preventive maintenance

• Avoid disruption of services by using non- invasive technology

• Benefit from technology that is quick and accurate for identifying potential hazards

• Reduce emergency service calls

Improve Safety

• Identify fire hazards

• Reduce risk of catastrophic system failure

Name*

admin

admin