HIGH AVAILABILITY MAINTENANCE MODEL

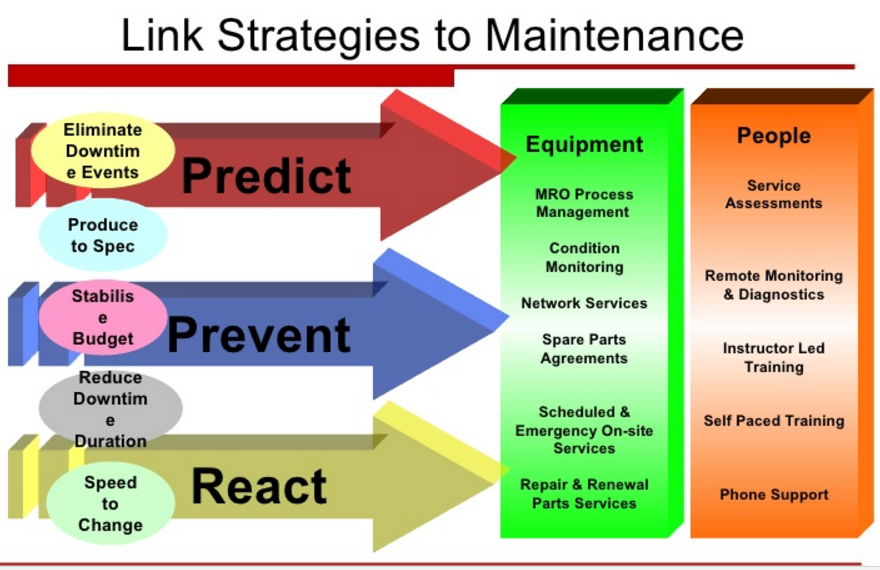

It is the most demanding and exhaustive maintenance model. It is applied to that equipment that under no circumstances may suffer a breakdown or malfunction. These are equipment to whom are also required very high levels of availability, above 90%. The reason for such high level of availability is generally high cost in production due to a fault. With a demand so high, there is no time to stop the equipment if the maintenance requires it (corrective, preventive, systematic).

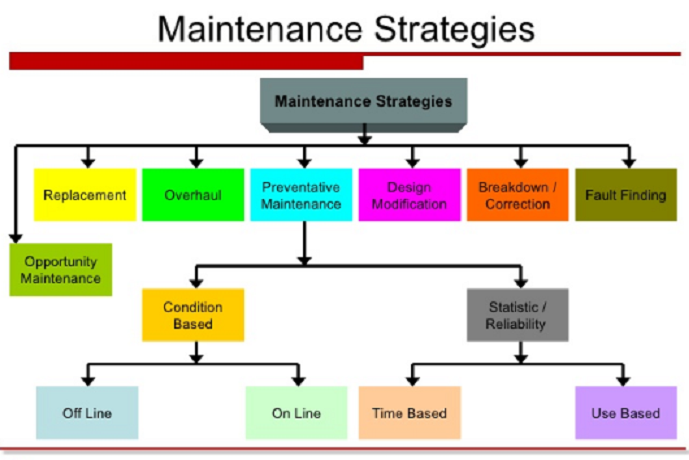

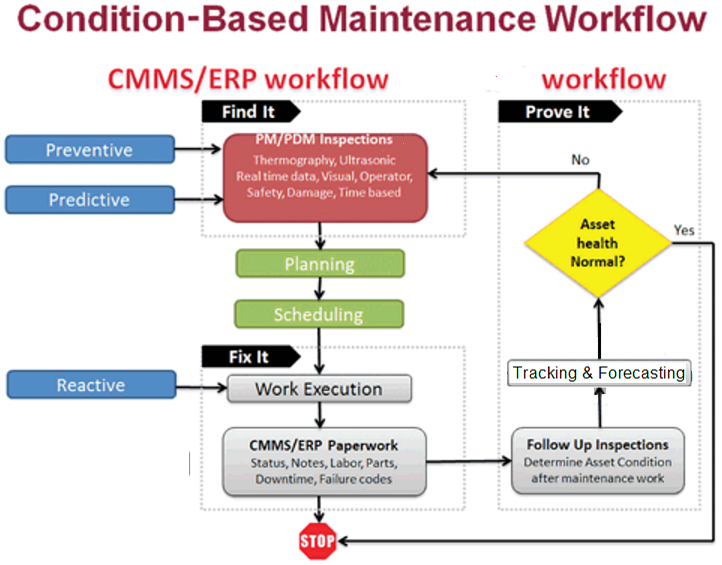

To maintain this equipment is necessary to use predictive maintenance techniques that allow us to know the status of the UPS when is working, and scheduled shutdowns, which supposes a complete overhaul, with a frequency usually semiannually & annually. This review will replace, in general, all parts subject to failure probability over the years. These reviews are prepared well in advance.

Since in this model the corrective maintenance is not included, that is, the aim should be zero breakdowns on this equipment.

Usually there is no time to properly address the issues that occur, being desirable in many cases quick provisional repairs that will maintain the UPS working until the next overhaul. Therefore, the Annual Overhaul must include the resolution of all those provisional repairs that have had to be made throughout the year.

Name*

admin

admin