Battery Maintenance Service

Batteries are the heart of the UPS and major of failures in UPS systems are due to batteries. Costs related to lost data or damaged critical load equipment can be very high, especially when compared to the cost of preventive maintenance. The primary objective of a battery maintenance program is to ensure that the battery system is able to meet the emergency run time requirements for the critical system to which it is connected.

Swiss Power Solutions provide a Battery Maintenance Program that can be adjusted to your specific battery types and specific needs. Appropriate load banking testing can provide predictive failure analysis of the batteries.

• IEEE 450 Maintenance and Testing

• IEEE 1188 Maintenance and Testing

Our leading Battery continuous maintenance packages include:

Weekly maintenance

Quarterly Maintenance

Semiannually maintenance

Annually maintenance

The Weekly Maintenance consists of the following:

1.Visual inspection of all cells

2.All connection visual check

3.Check of environment, temperature, dust, moisture, room vents,….

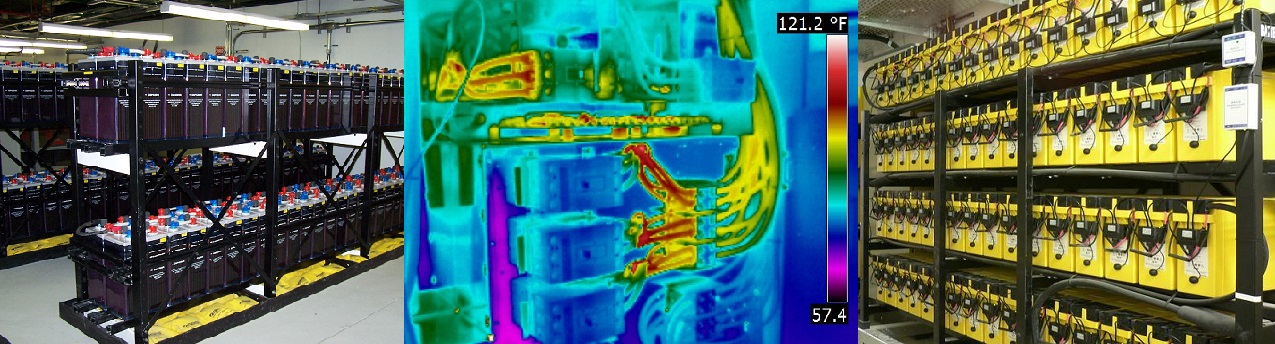

4.Take all measurements from the Battery Bank charging voltage , current.........)

5.Check the history indicated alarms from the UPS controller if the UPS was working on the batteries mode.

6.Tracking record & forecasting coordinates with our software data base system .

7.Provide computer analysis and historical archiving of all battery data and furnish an Weekly Maintenance Routine Report.

The Quarterly Maintenance consists of the following:

All points in the weekly maintenance will be done and In addition to the following:

1.Measure and record the specific gravity of every cell.

2.Measure and record individual cell and string float voltages.

3.Clean all cells and racks, provide corrosion control where required.

4.Adjust electrolyte levels as required.

5.Record temperature of electrolyte of representative pilot cells.

6.Individual cell inspection; seals sediment levels, positive and negative plates, flame arrestors, electrolyte levels.

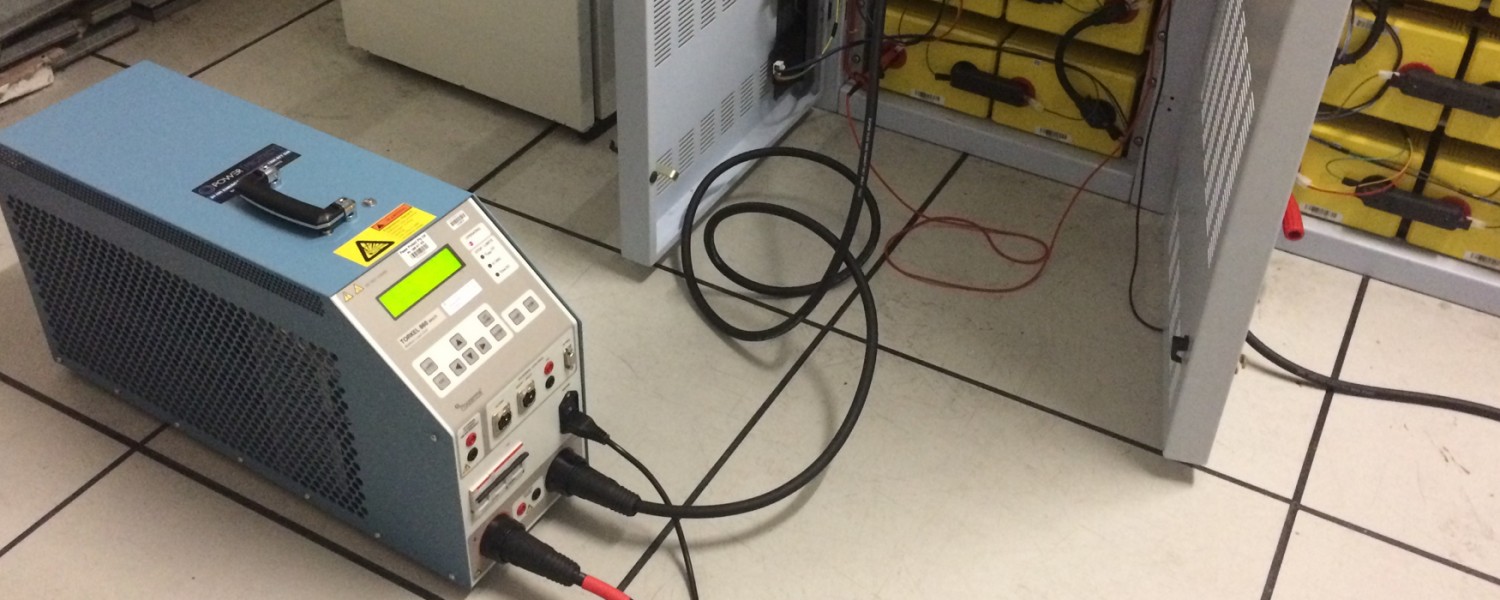

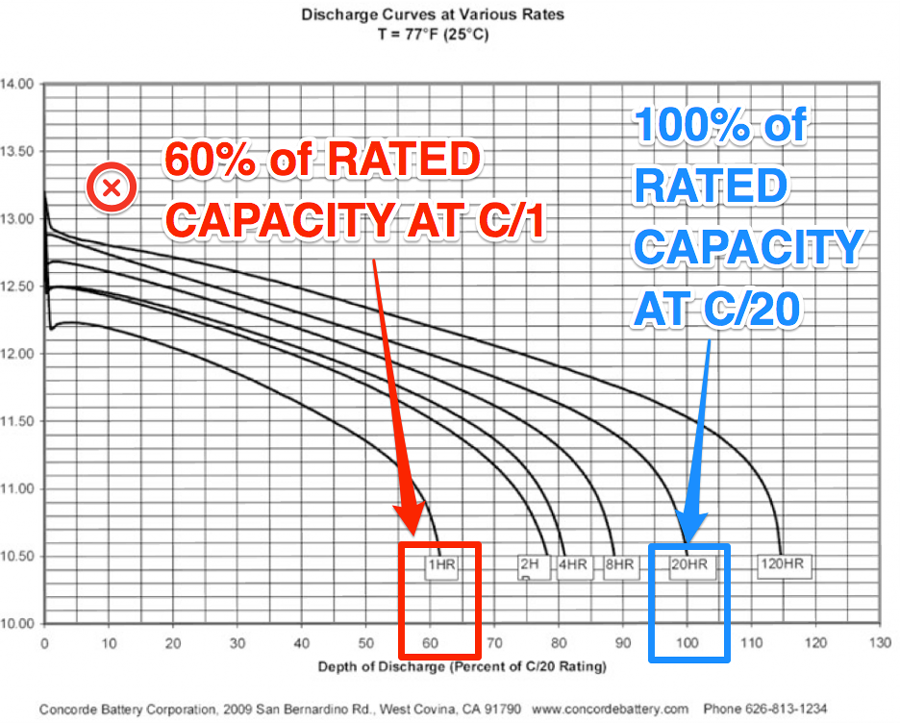

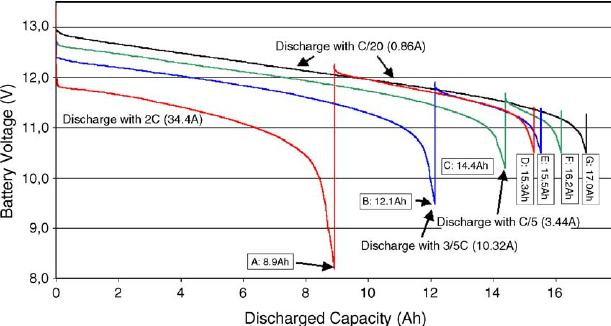

7.Individually High Rate/Short Term load test all jars to verify integrity and proper recovery curve.(sealed Battery)

8.Provide computer analysis and historical archiving of all battery data and furnish a Quarterly Maintenance Routine Report.

9.All distilled water to be supplied by customer or billed to customer.

The Semiannual Maintenance consists of the following:

All points in the Quarterly maintenance will be done and In addition to the following:

1.Perform digital low resistance ohm meter readings and inspection on all intercell and intertier connections.

2.Rehabilitate up to 20% of all connections as required by above test and inspection. All connections requiring rehabilitation over the 20% limit will be billed on a time and material basis.

3.Verify proper torque of all bolted connections.

4.Clean and neutralize all cells and racks.

5.Measure and record all individual specific gravity readings.

6.Measure and record all individual cell and string float voltages.

7.Individual cell inspection, seals, sediment levels, positive and negative plates, flame arrestors, electrolyte levels.

8.Adjust electrolyte levels as required.

9.Record temperature of electrolyte of representative pilot cells.

10.Verify integrity of the battery rack.

11.General cleanliness of the battery and battery room.

12.Individually High Rate/Short Term load test all jars to verify integrity and proper recovery curve.(sealed Battery)

13.Battery operation and return

14.Battery Thermal imaging test

15.Battery Calorimetry check

16.Provide computer analysis and historical archiving of all battery data and furnish an Annual Maintenance Routine Report.

17.All distilled water to be supplied by customer or billed to customer.

The annual Maintenance consists of the following:

All points in the Semiannual Maintenance maintenance will be done and In addition to the following:

1.Perform digital low resistance ohm meter readings and inspection on all intercell and intertier connections.

2.Rehabilitate up to 20% of all connections as required by above test and inspection. All connections requiring rehabilitation over the 20% limit will be billed on a time and material basis.

3.Verify proper torque of all bolted connections.

4.Clean and neutralize all cells and racks.

5.Measure and record all individual specific gravity readings.

6.Measure and record all individual cell and string float voltages.

7.Individual cell inspection, seals, sediment levels, positive and negative plates, flame arrestors, electrolyte levels.

8.Adjust electrolyte levels as required.

9.Record temperature of electrolyte of representative pilot cells.

10.Verify integrity of the battery rack.

11.General cleanliness of the battery and battery room.

12.Individually High Rate/Short Term load test all jars to verify integrity and proper recovery curve.(sealed Battery)

13.Battery operation and return

14.Battery Load Testing

15.Battery Thermal imaging test

16.Battery Calorimetry check

17.Battery Changing if needed.

18.Provide computer analysis and historical archiving of all battery data and furnish an Annual Maintenance Routine Report.

19.All distilled water to be supplied by customer or billed to customer.

Name*

admin

admin