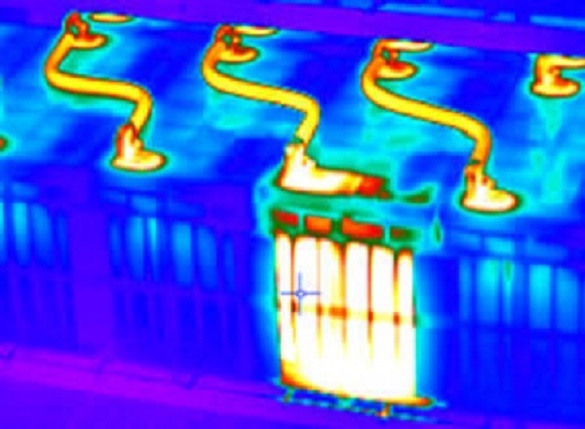

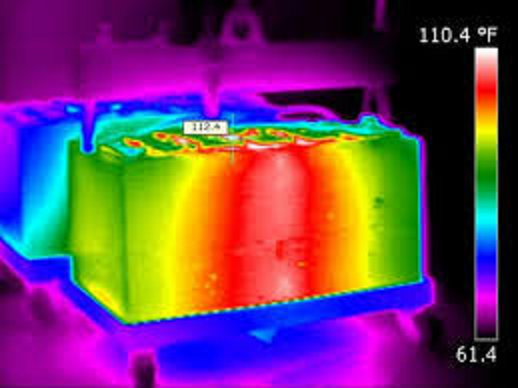

Battery Infrared Thermography

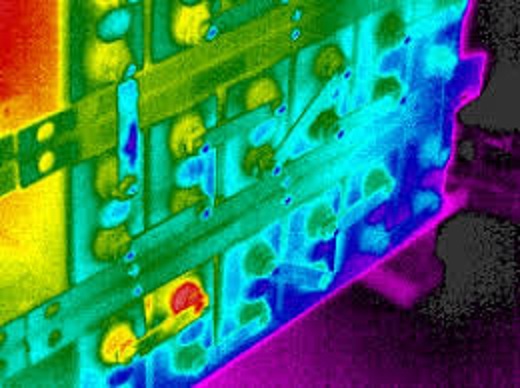

Swiss power Solutions thermography Service offers an in-depth report of your facilities that will help identify leaks, hot or cold spots within the Infrared electrical inspections find hot spots caused by defects in connections and components.Infrared thermography is used to find areas of excess heat (caused by increased resistance) so that problems can be corrected before a component fails, causing damage to the component, creating safety hazards and productivity loss. Because increased heating is a sign of failure, infrared is the best diagnostic tool available for finding these hot connections in the early stages of degeneration.

What are the advantages of Thermography Scanning?

The following are some of the advantages for using Thermography Scanning through the maintenance

1- Cost Savings

No other preventative method is as cost effective as thermal scanning. Thermal Scanning will assist you in minimizing your downtime, protecting your business.

2- Non-destructive Testing

We can easily identify heat related external anomalies without having to disconnect or destroy any equipment.

3- Building hazard reduction e.g. Reduces the possibility of fire

4- Early detection of potential faults

Name*

admin

admin